For 51 years, ACIMEX has been concentrating its efforts on vacuum as means of handling various loads in several industries such as metallurgy, concrete prefabrication or the aircraft industry. These years of experience have enabled the company to acquire unparalleled know-how in the field of vacuum handling.

How does vacuum handling work?

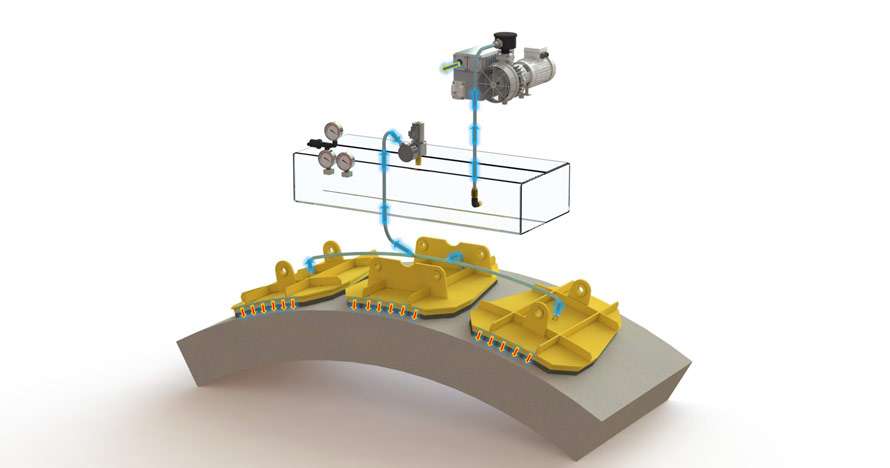

Vacuum handling using suction cups is simple. A pump sucks in the vacuum between the suction cup and the part to be lifted, and stores this vacuum in a chamber dedicated for this purpose.

By creating a vacuum, the atmospheric pressure is eliminated in the suction cup enclosure. The product is then pressed against the suction cup by this same atmospheric pressure of 1 kg/cm² (which varies from 950 to 1030 hectopascals); consequently, on a suction cup of 1 m² there is a pressure of 10,000 kg, making it capable of raising 4,000 kg, in accordance with European rules.

This physical phenomenon makes handling by suction cups an extremely efficient and reliable technique, capable of performing a very large number of handling operations.

Understanding the suction cup vacuum lifter in detail

Once the air is taken away from the suction cup, the pressure rises, the suction cup sticks to the surface and becomes one with the load. The vaccum thus created allows the lifting of tens of tonnes.

The strong points of ACIMEX products

- Custom design: the lifters can lift up to 30 tonnes of load, or more depending on the customer’s requirements.

- Diversity of loads: vacuum clamping enables effective lifting of concrete, tubes, plates and slabs.

- Ease of use: the part can be picked up and put down instantly using a simple push button.

- Safety: the vacuum level is continuously monitored to detect leaks and to warn you when the load needs to be put down.

- Improvement in productivity: vacuum handling requires only a few seconds compared with several minutes with traditional mechanical means.

- Integrity: thanks to the use of special rubber, suction cup handling leaves no marks even on very delicate surfaces.

- Ease of implementation: suction cup lifting is handling by the top: the positioning and reversal of the load are simple and easy operations (installation of slabs, fitting of windows, installation of machine parts, etc.).

Comparison of ACIMEX products with other solutions on the market

| Advantages of the ACIMEX SUCTION CUP vacuum technology | ||

| compared to | ||

| STEEL PLATE handling | The vacuum system is precise and only takes one plate at a time regardless of the thickness. | A magnet may accidentally take several plates at a time |

| The vacuum system respects the integrity of the panel: no marks or deformation | A clamp can mark or deform the metal plate | |

| The vacuum system is compatible with all metals | The magnet is not compatible with stainless steel or aluminium | |

| The vacuum system is a source of energy saving: the supply and the power are standard | A magnet requires a lot of electrical power | |

| The vacuum system is compatible with all systems: no modification to the lifting system | A magnet is heavy and bulky | |

| CONCRETE, STEEL or PVC PIPES and TUBES handling | The vacuum system respects the surface and geometry of the panel: no marks or deformation | Hydraulic and mechanical clamps: risk of marking, damage or even distortion of the coating |

| The vacuum system is fast, the gripping time is estimated at 1 second | Mechanical clamps or slings require a longer application time, (adjustment at the ends / passage under the pipe) | |

| The vacuum system requires no labour on the ground | Mechanical clamps or slings require 1 or 2 people working on the ground | |

| The vacuum system can operate in energy autonomy | Hydraulic clamps require an input of external energy (hydraulic or electrical source) | |

| The vacuum system is remotely managed, the risk of accidents to the personnel is zero | Mechanical clamps or slings present the potential risk of an accident because there is manual handling when putting the load down. | |

| Handling of the concrete parts: WALLS, SHEET PILING, SLABS, CHAMBERS and VATS | The vacuum system combines several movement functions = 1 single seamless demoulding and turning or tipping cycle | Mechanical clamps or slings do not offer continuous handling: reloading at every new operation. |

| The vacuum system is fast: a cycle takes 5 minutes | Mechanical clamps or slings: longer time for attaching/detaching clamps and slings | |

| The vacuum system requires no attachment point and represents a saving on the purchase of hooks and hanging points. | Mechanical clamps or slings require the purchase and implementation of points of attachment (hanging points, nuts, etc.) for the demoulding phase. | |

| The vacuum system makes it possible to distribute the force onto any part of the part during demoulding = the risk of cracks is greatly reduced | Mechanical clamps or slings concentrate the mechanical forces at the hanging points, the risk of cracks or breakage are high | |

| The vacuum system allows perfectly vertical demoulding | Mechanical clamps or slings present a risk of cracking or jamming of the concrete part (non-vertical positioning) | |

| The vacuum system allows parts to be placed edge to edge without catch points | Mechanical clamps or slings are not compatible with edge to edge installation | |

| The vacuum system preserves the concrete part: no cracks, or breaks on the fresh product after 6 to 8 hours of drying | Hydraulic clamps damage the concrete part and require more than 6 to 8 h for drying before demoulding | |